GMH Extended Equipment Life, Cut Costs, and Accelerated Delivery with MoldJet® Technology

GMH extended equipment life, cut costs, and accelerated delivery with MoldJet® technology.

Read More

GMH extended equipment life, cut costs, and accelerated delivery with MoldJet® technology.

Read More

How Exalta Reached Superior Surface Finish and Scalable Production with Lower Costs

Read More

Precision where it matters - variable layer thickness (VLT)

Read More

How BAARS ensured outstanding surface quality using MoldJet for mass production

Read More

Learn how to improve the density of printed green bodies while preserving their complex shapes through CIP and MoldJet.

Read More

Boosting Green-to-Green Sinter Bonding Strength with a Simple Method

Read More

MoldJet process enables the manufacturing of completely hollow parts without requiring any modifications to the original design.

Read More

From material development through repeatable, reliable production

Read More

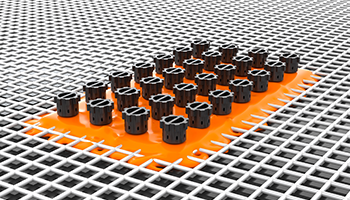

MoldJet technology enables industrial-scale manufacturing of various complex geometries. For improved surface finish, the parts may undergo a short cycle time labor-free “green state” post-process.

Read More

Finding the optimal angle for walls being manufactured along the Z axis, will reduce the need for post processing to achieve a uniform finish.

Read More

The MoldJet process enables the manufacturing of green parts with high strength and density

Read More

Using MoldJet technology to manufacture male threads. Fine threads M3-M8 are functional at the ‘at sintered’ stage.

Read More

Our MoldJet technology enables serial production using a wide range of materials.

Read More

Learn about applications for Defense & Aerospace industries using MoldJet technology

Read More

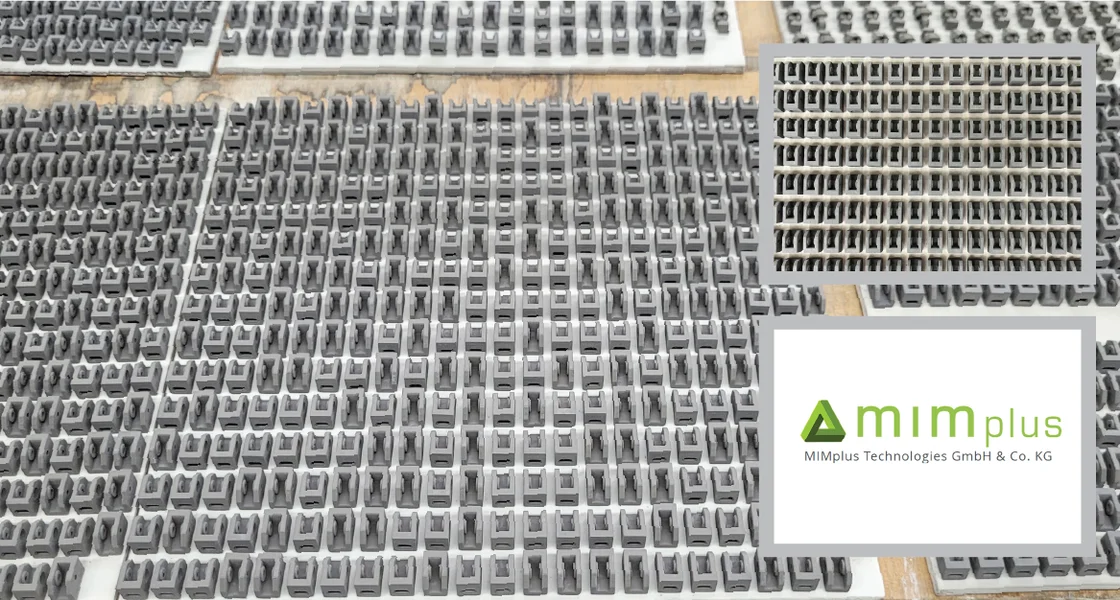

Learn how Deutsche Bahn utilized MIMplus metal parts for first-class train seats.

Read More

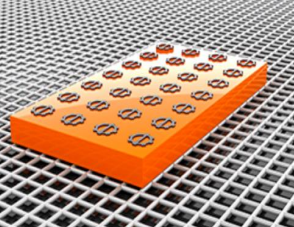

How to predict the behavior of parts during the sintering process by using Ansys Additive Suite simulation

Read More

learn how Fraunhofer uses moldjet technology to ensure quality of metal parts

Read More

How to prepare your desired part for printing using MoldJet technology

Read More

Learn about the safer, flexible, cost-efficient AM challenger to LPBF

Read More

How to reduce cost, time and man operations in creation of threaded parts

Read More

How to achieve a high-quality and repeatable output of parts in an industrial production

Read More

See how with Alphacam and Fraunhofer operate using MoldJet technology

Read More

How MoldJet AM technology is used to reduce lead-time and cost of metal parts.

Read More

The latest innovative approach to metal AM, enabling production of high-quality parts.

Read More

Ensuring quality during manufacturing and offering unlimited freedom of design.

Read More

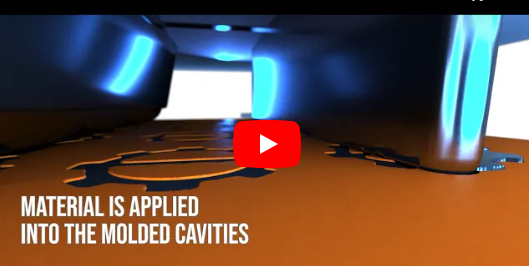

Learn how MoldJet technology works layer-by-layer to reach the final model.

Read More

How to swiftly produce intricate 3D chocolate shapes in large quantities

Read More