Increasing Green Density with CIP

Additive Manufacturing (AM), which uses sintering of printed green bodies, allows for complex geometries that traditional compaction methods can’t achieve. However, these parts often suffer from low density and high porosity, reducing their mechanical strength. Cold Isostatic Pressing (CIP) improves uniform compaction, but applying it to intricate shapes is challenging due to issues like sealing and structural collapse. Tritone's MoldJet technology addresses this by printing metal or ceramic powders inside a wax mold that also acts as a seal and support during CIP. This project focused on enhancing green body density while maintaining complex shapes using CIP and MoldJet.

Read the full researchLearn how to increase green parts density

-

Additive Manufacturing enables complex geometries but often results in lower density and higher porosity, compromising mechanical properties.

-

Cold Isostatic Pressing can improve part density but poses difficulties when applied to complex shapes, especially in sealing and maintaining structural integrity.

-

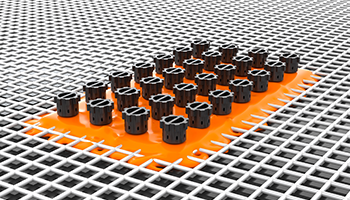

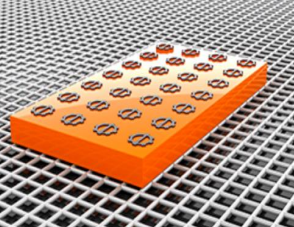

MoldJet technology prints metal or ceramic pastes within a wax mold that acts as both a sealant and structural support during CIP, helping preserve shape while enhancing density.