MoldJet Technology

At the heart of Tritone’s innovation lies MoldJet® technology — a powder-free additive manufacturing process that redefines how metal and ceramic parts are made. Built for true industrial production, MoldJet combines precision with speed, enabling the creation of complex geometries that meet the highest mechanical and density standards. Its flexible, tool-free workflow allows manufacturers to switch effortlessly between a wide range of metal alloys and ceramics, producing parts of different shapes and applications in the same batch. The result is a seamless, scalable production process that brings efficiency, versatility, and reliability to additive manufacturing.

Moldjet Manufacturing Solution

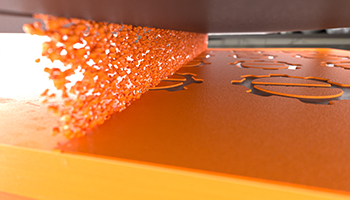

Placing a mold layer

Jetting layers of mold forms cavities of the inverse part contour geometry.

Pasting a part layer

High density paste is forced into all cavities of the build layer.

Drying & Hardening

Layer is rapidly dried and hardened, by hot air and vacuum.

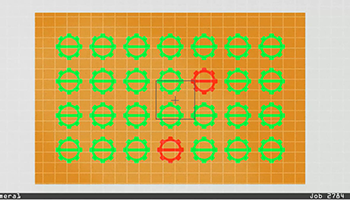

Optical Inspection

Real time AI image analysis followed by auto-correction / layer removal if required.

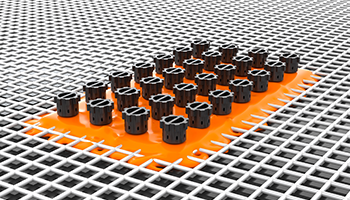

Finished Build Tray

When removed from the system the tray contains robust green parts embedded in stable hard mold material.

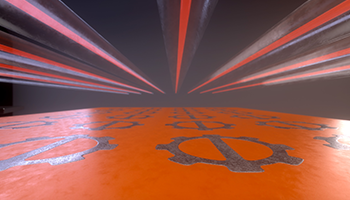

Demolding

A hands-free process, mold material is melted away to reveal green parts which are then rinsed in a solvent bath to prepare for sintering.

Thermal Debinding & Sintering

Finally, debinding and sintering are done in a single stage. The green parts become functional end-use metal / ceramic parts.

Key advantages

High throughput end to end

- Uniform, repeatable manufacturing across trays, high density (> 99%), and accuracy of parts

- Real time AI analysis followed by auto-correction / layer removal if required

- Range of sizes; 0.2mm up to 350mm

Any material at an industrial scale

- System supports both metal alloys and ceramic

- Based on standard MIM powders

- 30 minute material changeover -Quick, safe, and clean

Green & safe industrial environment

- A powder-free process, enabled by a paste-based feedstock

- Hands-free post process

- Low energy consumption, operates in standard industrial environment

- Easy and safe handling of green parts

the INDUSTRIAL solution for metal and ceramic manufacturing

We developed metal and ceramic additive manufacturing to meet the high standards of industrial production.

Our technology empowers efficient production of precise parts in various metals and ceramics, serving industries such as defense, Aerospace, Medical devices, tooling and more.