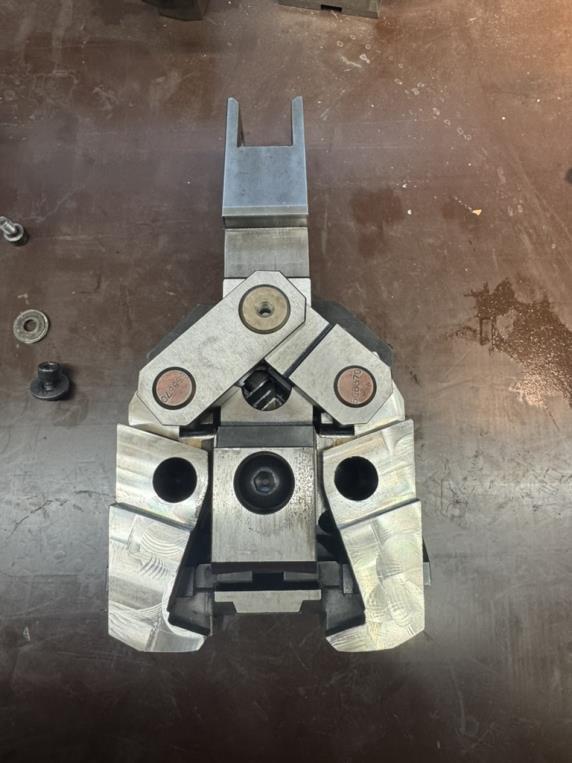

How GMH extended equipment

life, cut costs, and accelerated delivery with MoldJet®

GMH transitioned from conventional CNC machining to on-demand production of 17-4PH grippers using MoldJet. The new material and process enabled superior mechanical strength, reduced wear, and higher repeatability.

DOWNLOAD THE CASE STUDYPro Materia by GMH Group manufactured their gripper jaws using MoldJet which led to:

- Cost Down X5

- Service life increased by 300%

- longer life time

Download the case study

With the speed of delivery for the grippers, we were really impressed.

These ones are much better than the old ones — no question.

It’s a real improvement, even considering cost, maintenance,

and downtime.

Now these things, they just run — proper solid, like it should be.

Timm Hehemann, Operator, GMH Gruppe