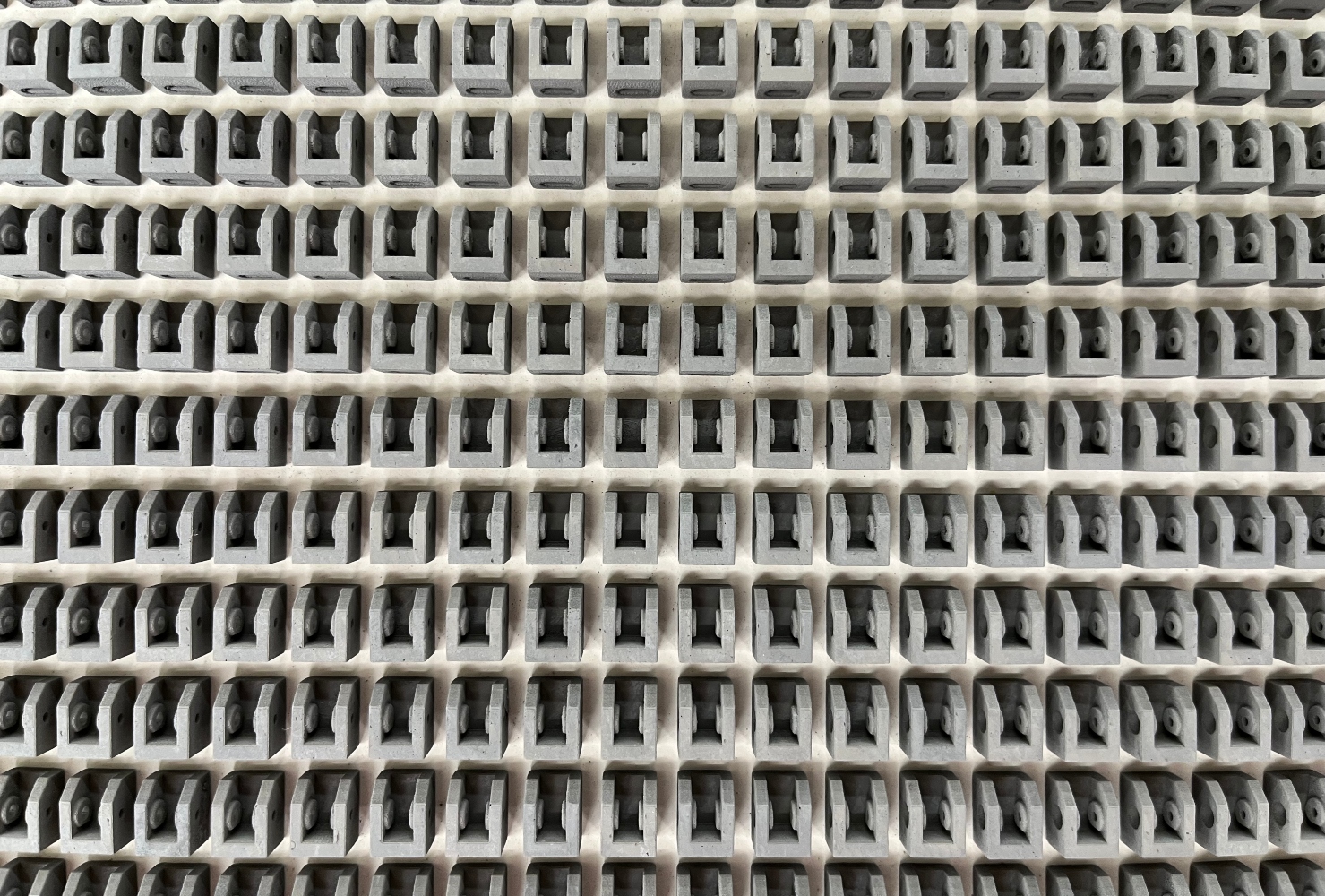

16,000 Hinges, Zero Compromise: The BAARS–MIMplus Success Story

BAARS set out to scale the production of its iconic eyeglass hinges without compromising on precision or design. To achieve this, the company partnered with Mimplus, who leveraged Tritone’s MoldJet® technology to overcome the limitations of traditional additive manufacturing. The collaboration enabled scalable, cost-efficient mass production—delivering 16,000 high-precision hinges for 4,000 eyeglasses with consistent quality and design freedom.

DOWNLOAD THE CASE STUDYDiscover how by using MoldJet technology, MIMplus were able to:

- Producing eyewear hinges with uncompromised precision and efficiency

- Combine design with scalable production

- Effortlessly manufacture thousands of parts to meet market needs

Download the case study

We are extremely satisfied with both the surface quality and

dimensional consistency of the parts.

Our end customers have given very positive feedback.

The collaborative development environment with Tritone, OBE,

and MIMplus has been outstanding.