The Bigger Picture

Across industries, manufacturers are pushing additive manufacturing (AM) beyond prototyping and small-batch production — into the realm of true industrial-scale manufacturing. Yet despite enormous progress, producing metal and ceramic parts at volume continues to challenge the limits of traditional AM technologies.

Processes such as laser powder bed fusion and binder jetting often excel in complex geometries but struggle to balance speed, quality, and cost when scaling up. For many manufacturers, this gap has become the central obstacle to achieving the long-promised “factory of the future.” They need a production method that delivers the design flexibility of additive manufacturing with the efficiency and consistency of conventional methods.

The industry has been searching for a technology that meets all three demands — volume, quality, and speed — without forcing compromise.

The Challenge

High-volume production requires more than just throughput — it demands repeatability, dimensional precision, and surface quality across thousands of parts. For metal and ceramic components, these factors are especially critical: even minute deviations can render parts unusable in demanding applications.

Traditional AM processes often require post-processing or manual finishing to meet cosmetic or dimensional standards, adding time and cost. As a result, manufacturers seeking to produce tens of thousands of precision parts have faced a dilemma: AM provides design freedom but not industrial scalability.

This was precisely the challenge that faced MIMplus Technologies, a German manufacturer with deep expertise in metal injection molding (MIM) and advanced sinter-based processes. When BAARS, a Paris-based eyewear brand, approached MIMplus to help produce thousands of high-precision magnetic hinges, the team knew that traditional AM alone would not meet the volume, surface finish, and cost targets required.

The Collaboration

To meet these ambitious requirements, MIMplus explored emerging solutions capable of scaling additive manufacturing for industrial production. The company identified the MoldJet® system as a viable path forward — not as a replacement for established methods, but as a bridge between AM flexibility and mass-production capability.

MIMplus leveraged MoldJet® to manufacture metal hinges for thousands of eyeglass frames, achieving consistency and aesthetic precision that aligned with BAARS’ minimalist design philosophy. The process allowed for decorative surface finishes and layered textures to be intentionally incorporated into the design — without compromising structural integrity or efficiency.

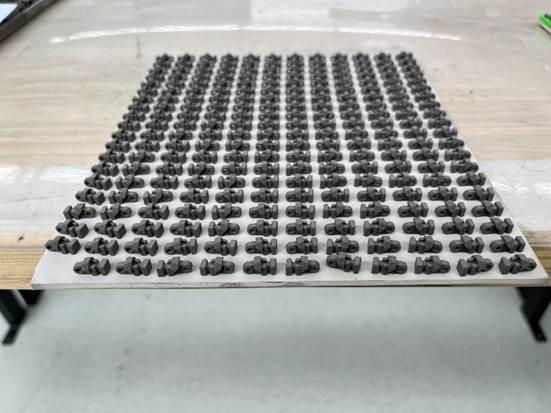

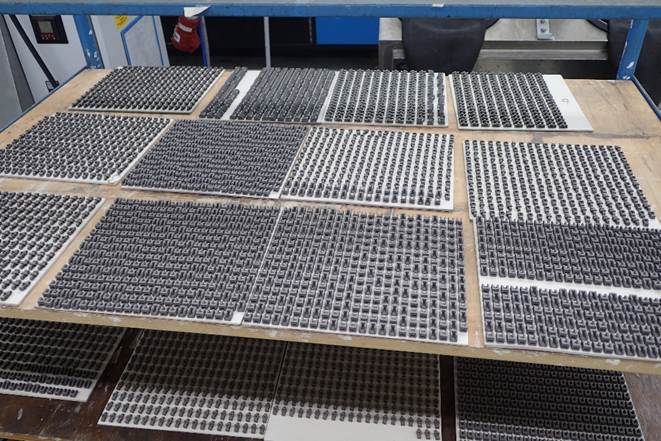

By using MoldJet®, MIMplus could produce up to 16,000 parts (for 4,000 glasses), with 800 parts per tray, all completed in under 20 hours. This represented not just a technical achievement, but a demonstration of how additive manufacturing can scale to meet industrial demand.

Results and Impact

The results were immediate and measurable.

- High-resolution accuracy ensured each hinge maintained its functional reliability and visual precision.

- Outstanding surface quality eliminated the need for additional polishing or finishing, critical for customer-facing components.

- Scalable throughput allowed thousands of identical parts to be produced quickly and economically.

BAARS’ own feedback underscored the success of the project:

“We are extremely satisfied with both the surface quality and dimensional consistency of the parts. Our end customers have given very positive feedback. The collaborative development environment with Tritone, OBE, and MIMplus has been outstanding.”

Beyond this specific application, the project demonstrated how sinter-based additive manufacturing can rival — and even complement — traditional production methods when managed in an industrial workflow.

A New Chapter for Industrial Manufacturing

This collaboration marks a broader shift in the evolution of AM: the transition from innovation at the prototype level to production at industrial scale. Technologies like MoldJet® are enabling manufacturers to think differently — to bring the design freedom of additive manufacturing into high-volume, high-precision production without compromise.

For companies like MIMplus and BAARS, this capability opens doors to faster iteration, reduced inventory, and sustainable, on-demand production models. For the manufacturing industry, it signals that industrial additive manufacturing is no longer a future vision — it’s a present reality.