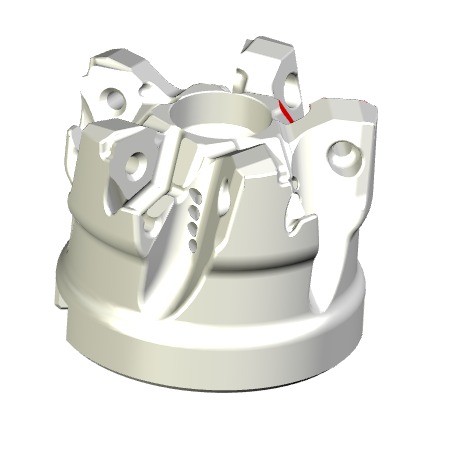

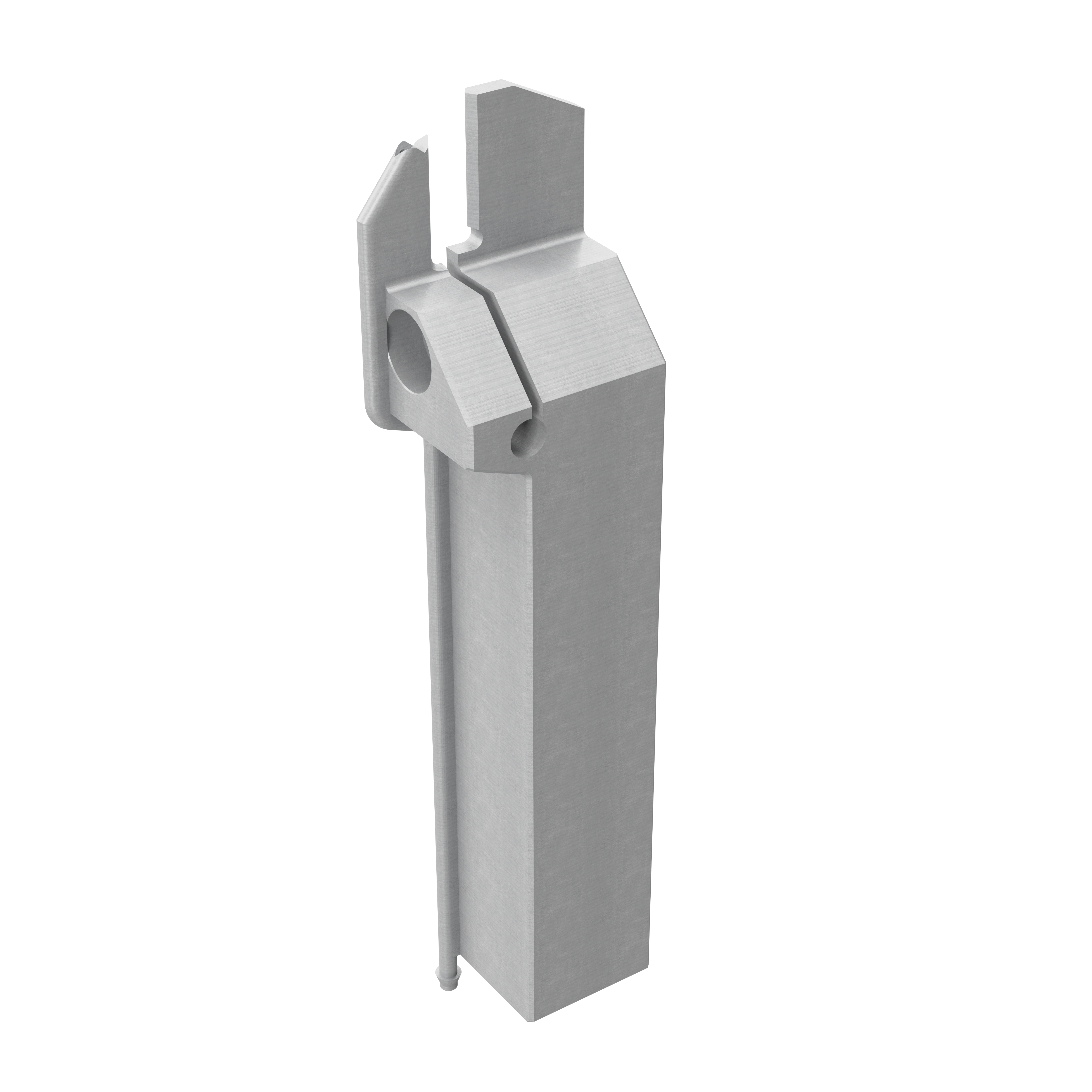

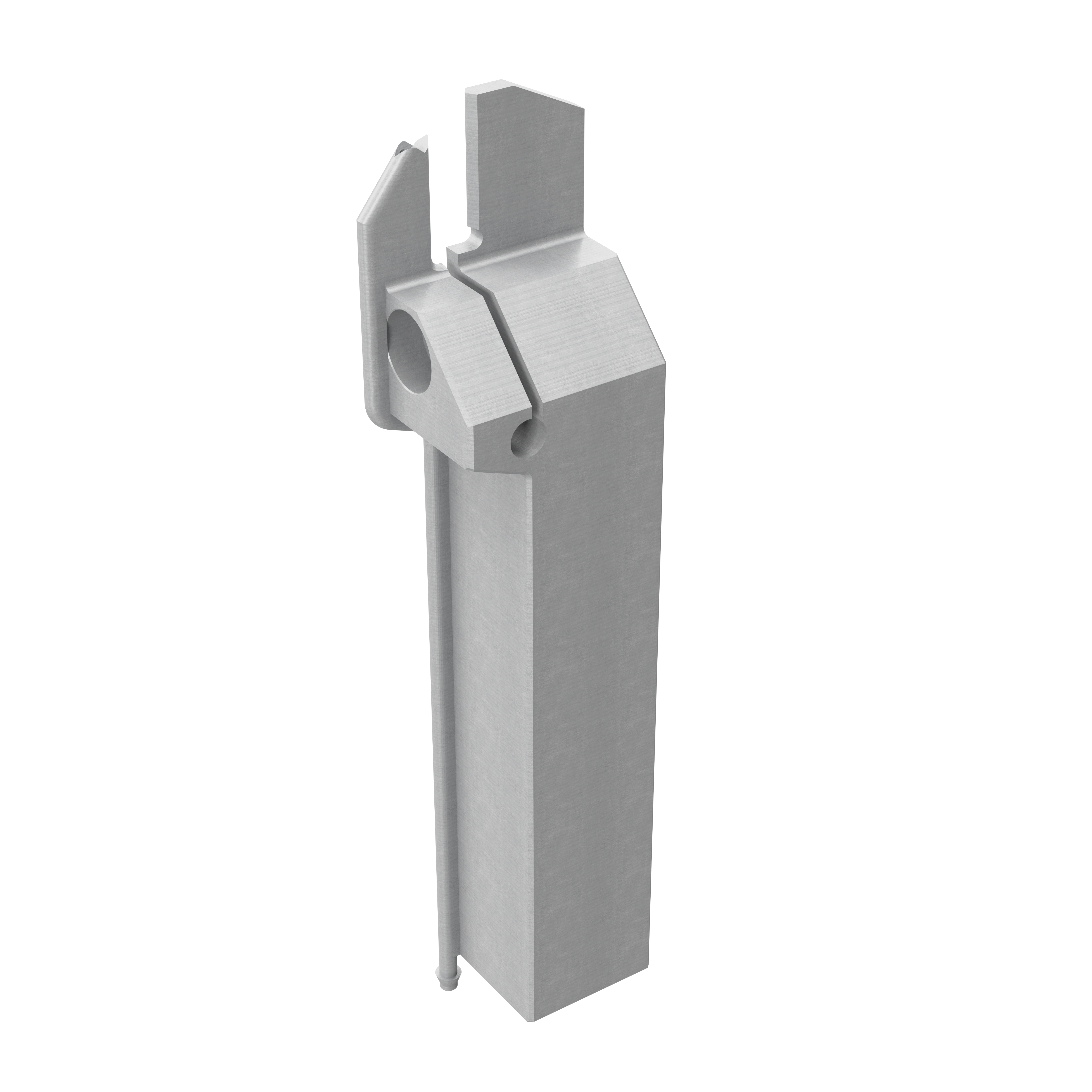

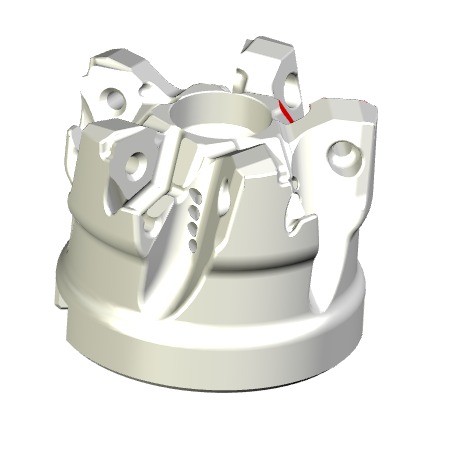

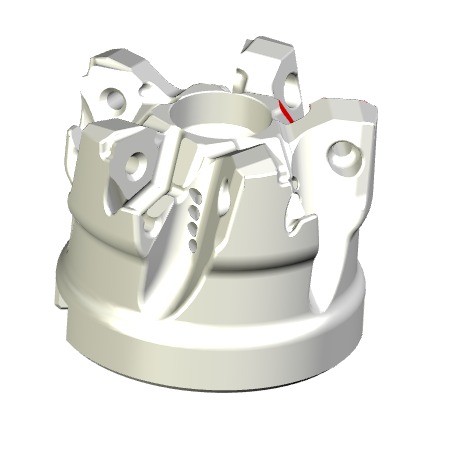

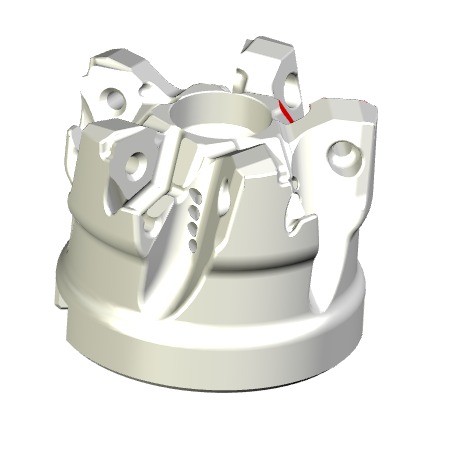

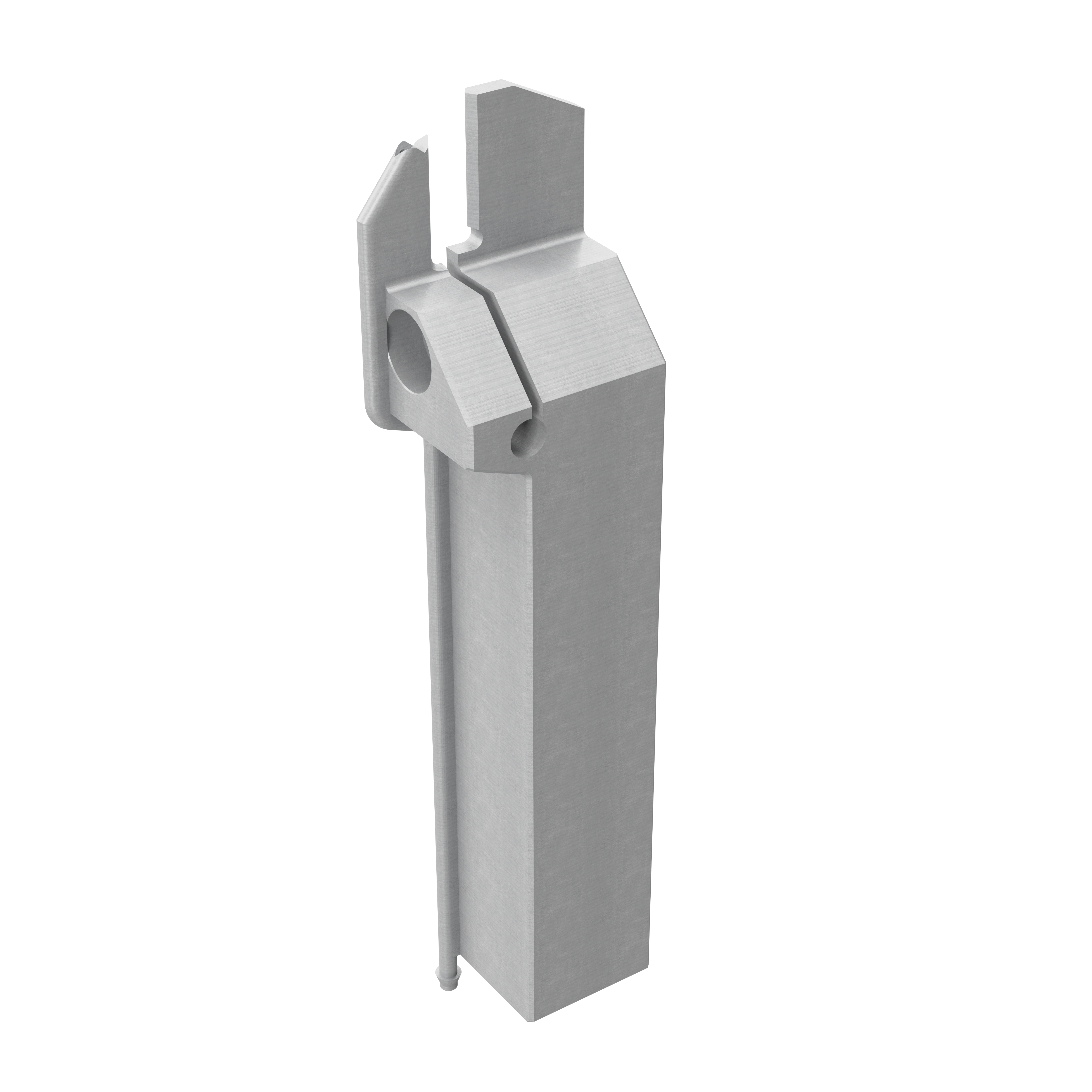

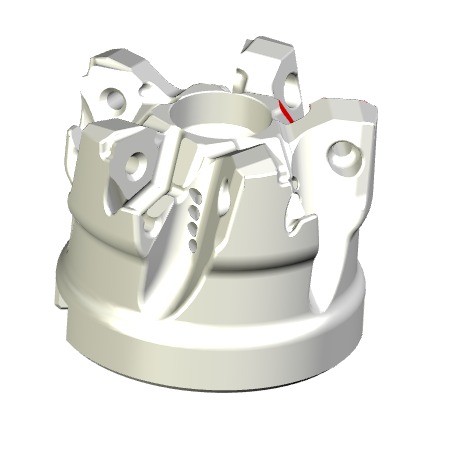

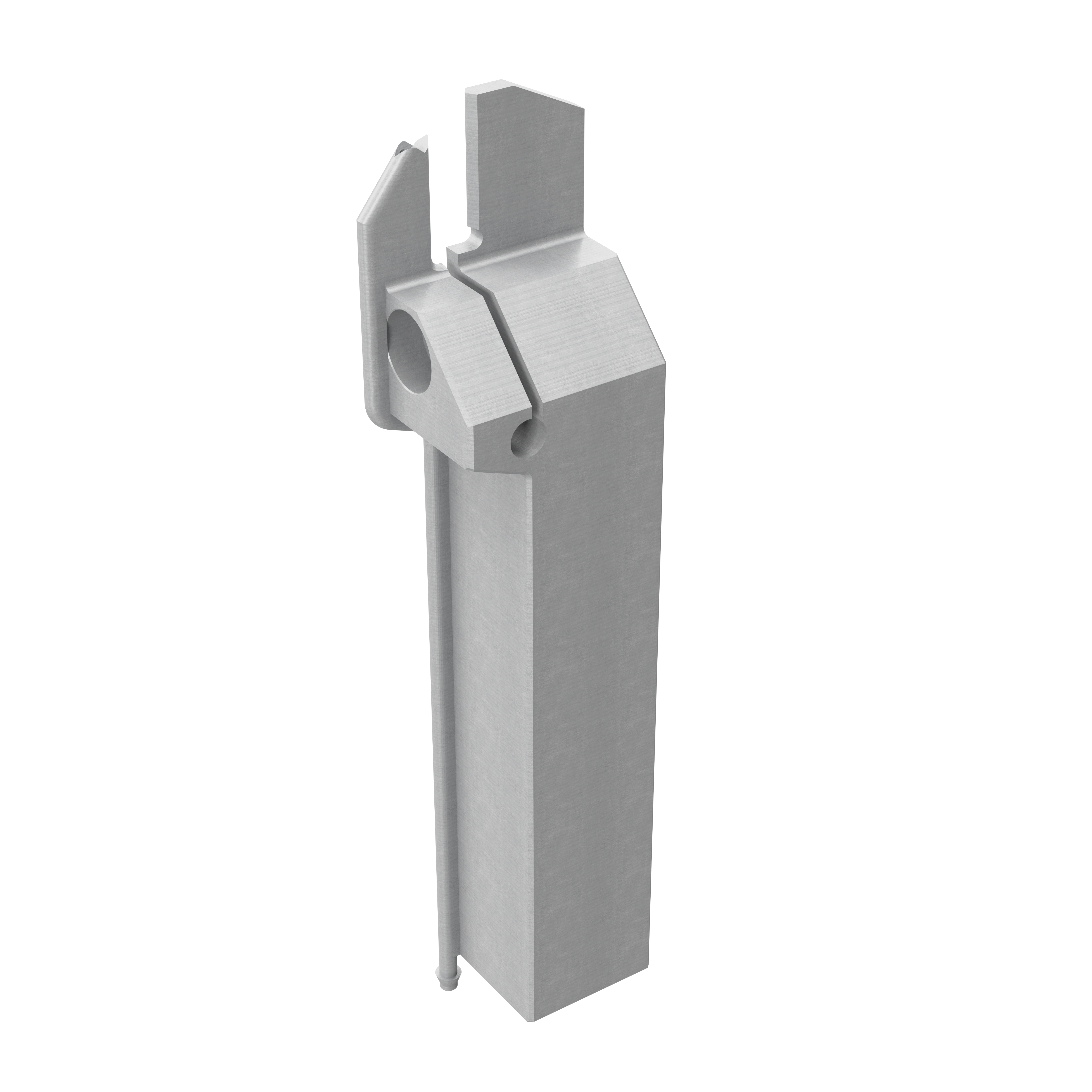

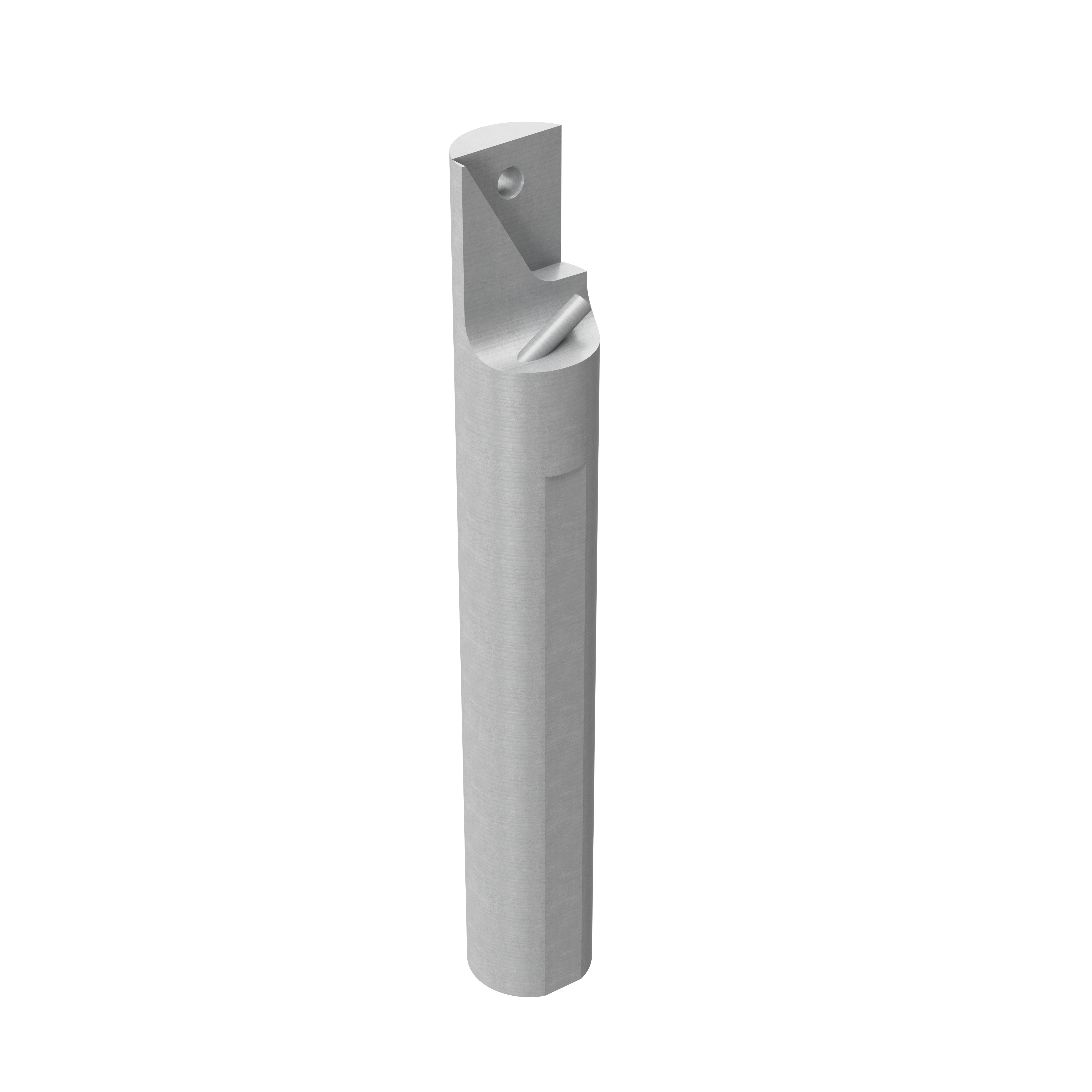

Milling Cutter Body

Ti-64

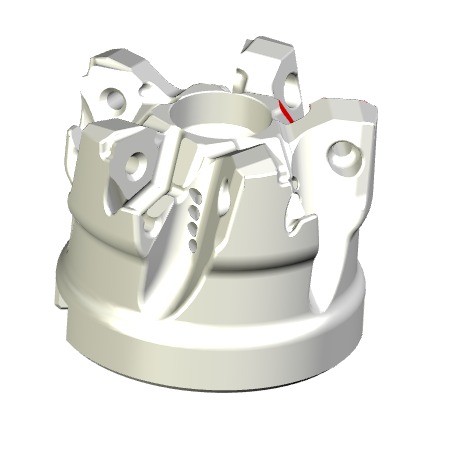

Enhancing Performance and Precision with MoldJet Technology

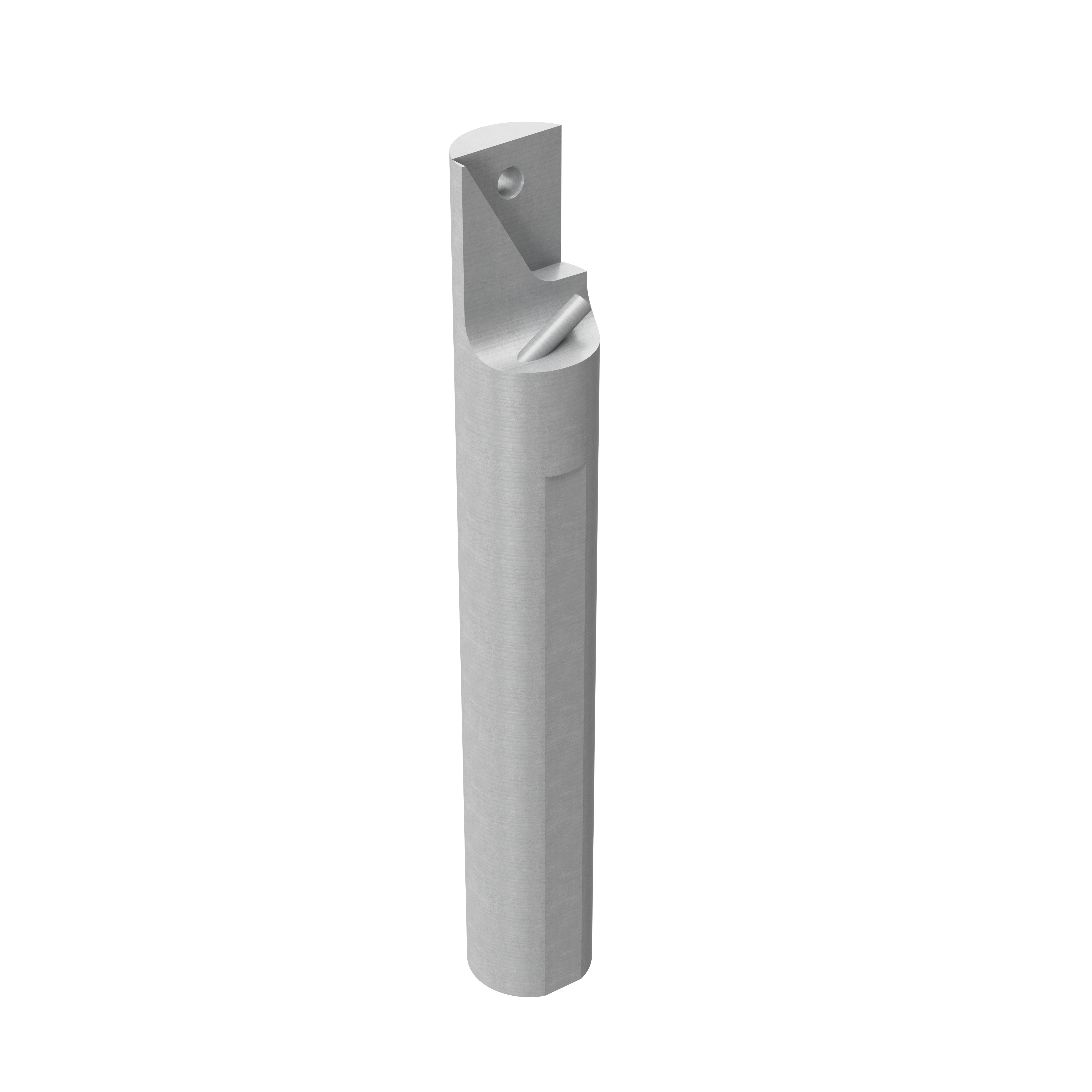

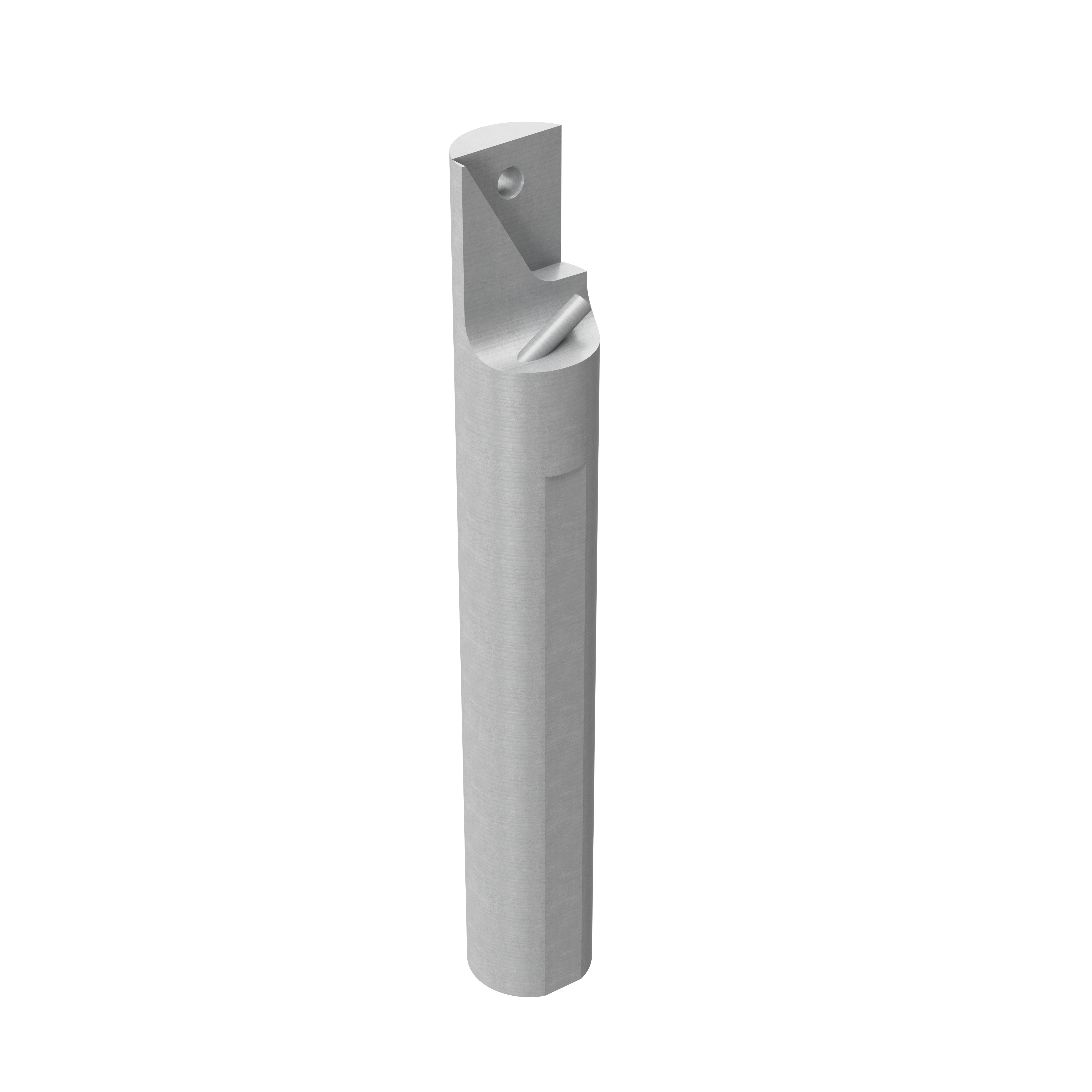

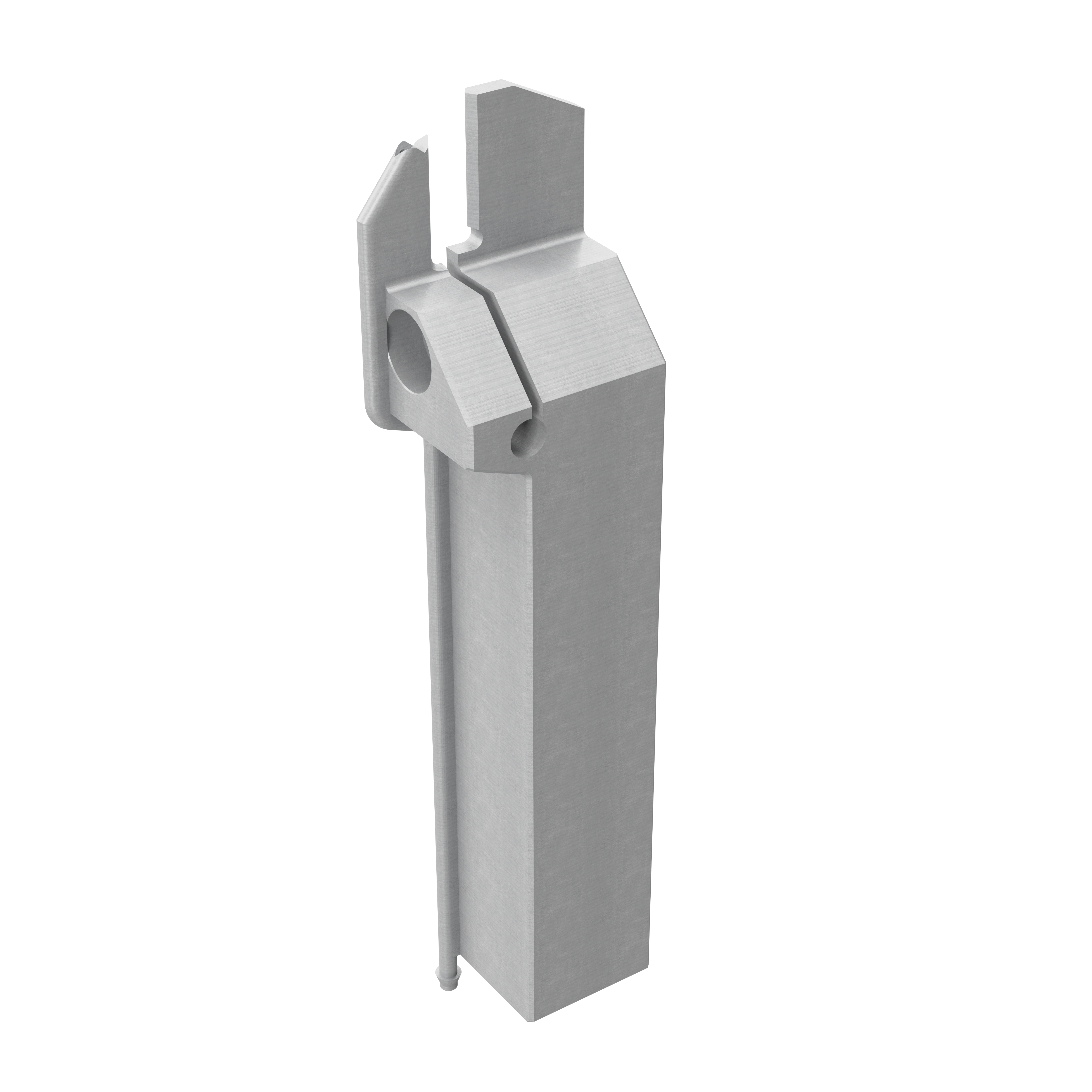

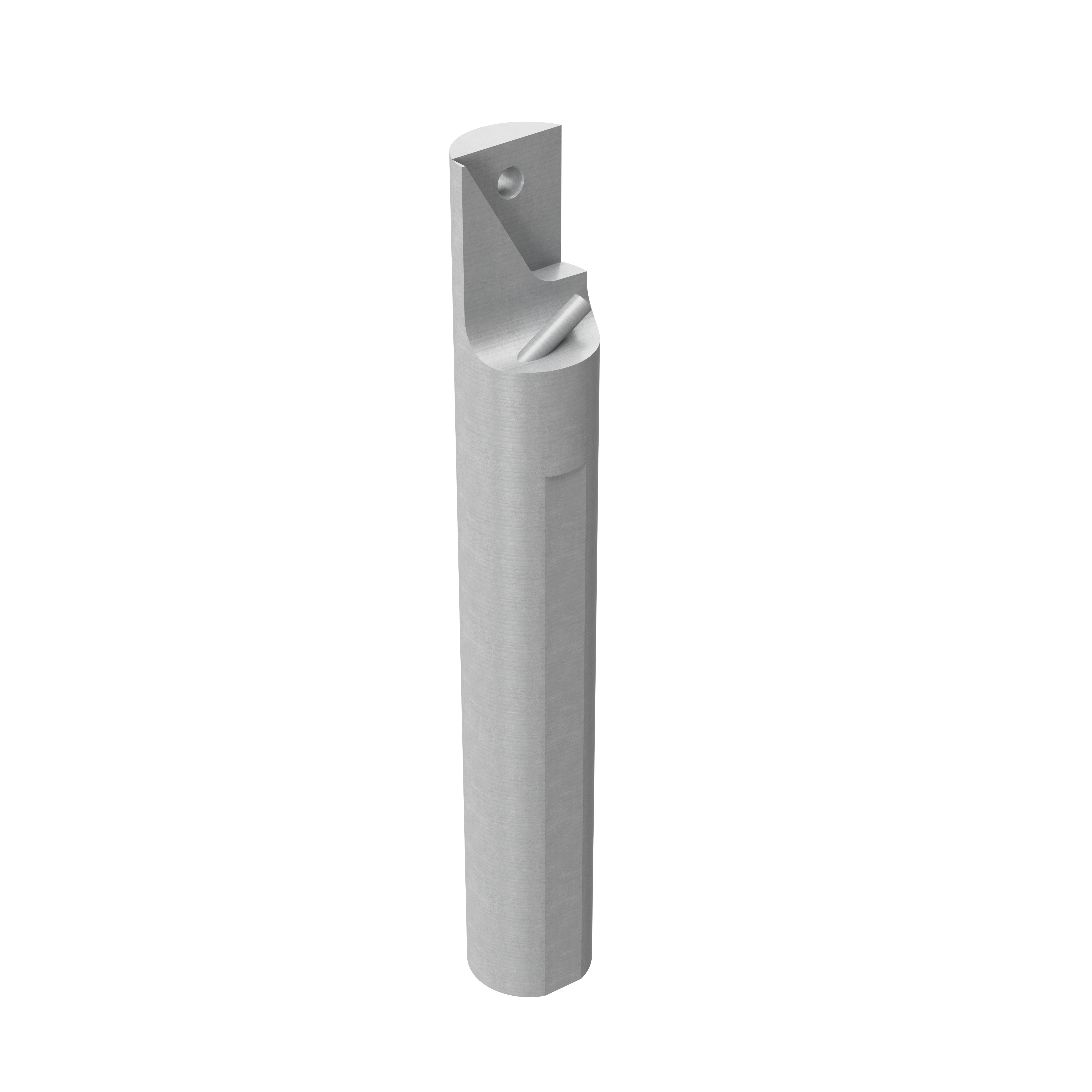

Tritone’s MoldJet technology empowers tooling designers to achieve unprecedented performance in cutting tools and holders. Our unique powder-free process unlocks the ability to produce intricate channels, undercuts, and internal structures, eliminating the need for post-processing powder removal and ensuring superior part quality.

MoldJet technology allows for the creation of highly customized tooling components with an expanding range of tool steels and hard metals, perfectly tailored to meet the demanding requirements of various tooling applications.

From nozzles and drill heads to turbine wheels customized screws, Tritone’s MoldJet technology delivers unmatched versatility and precision. Explore a wide range of tool steels and hard metals, enabling you to select the perfect material for your specific tooling application

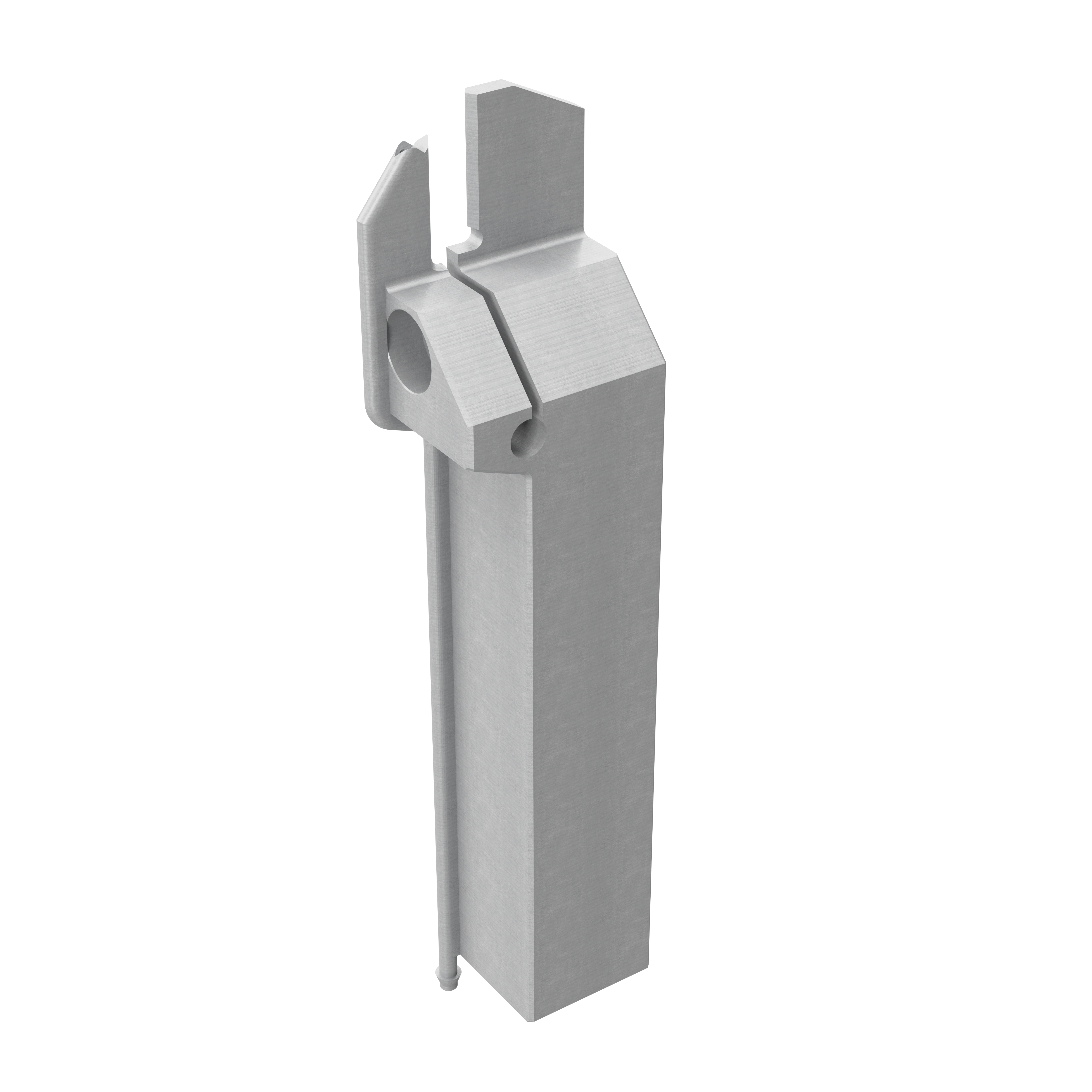

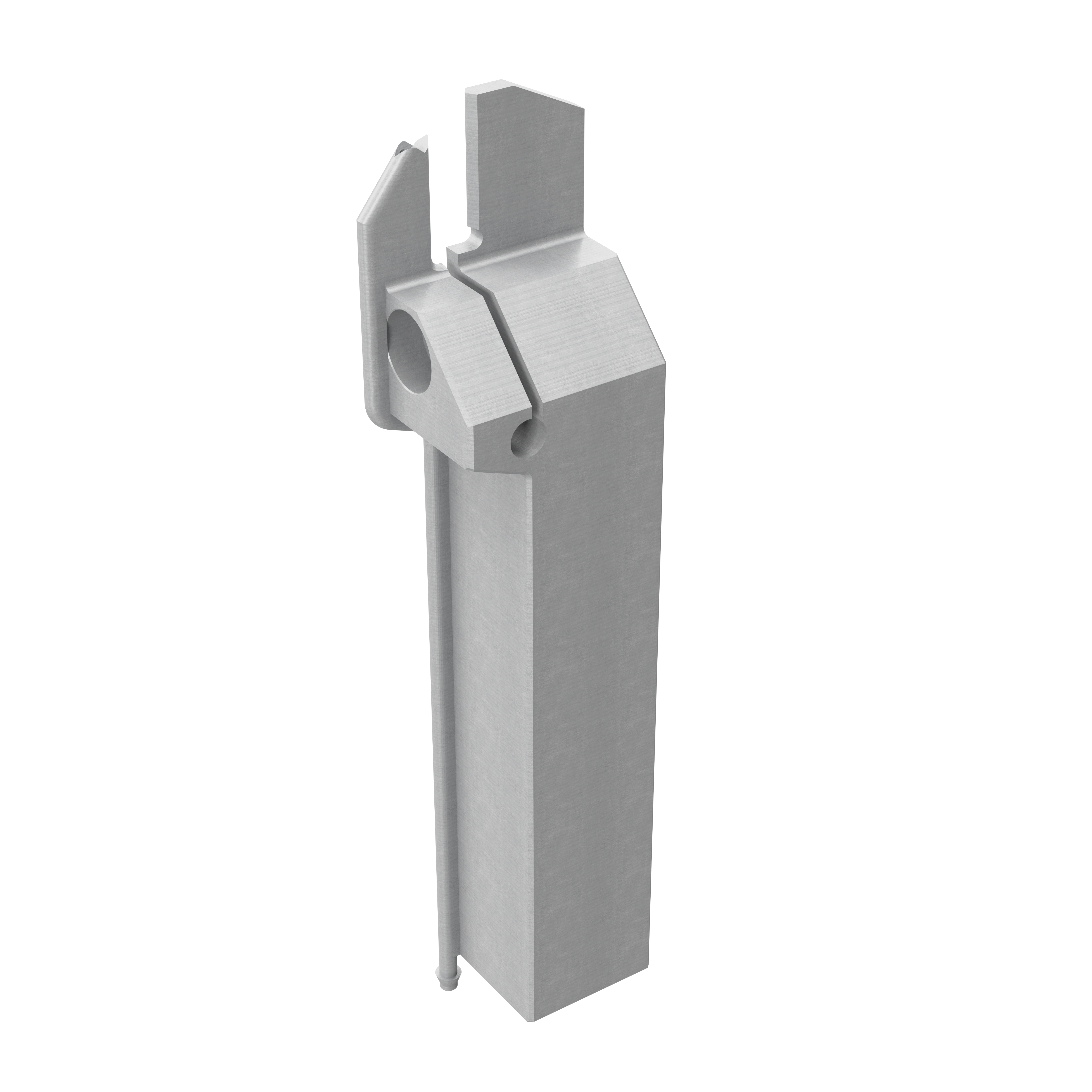

Ti-64

17-4PH

H13

Tungsten carbide (WC)

Titanium

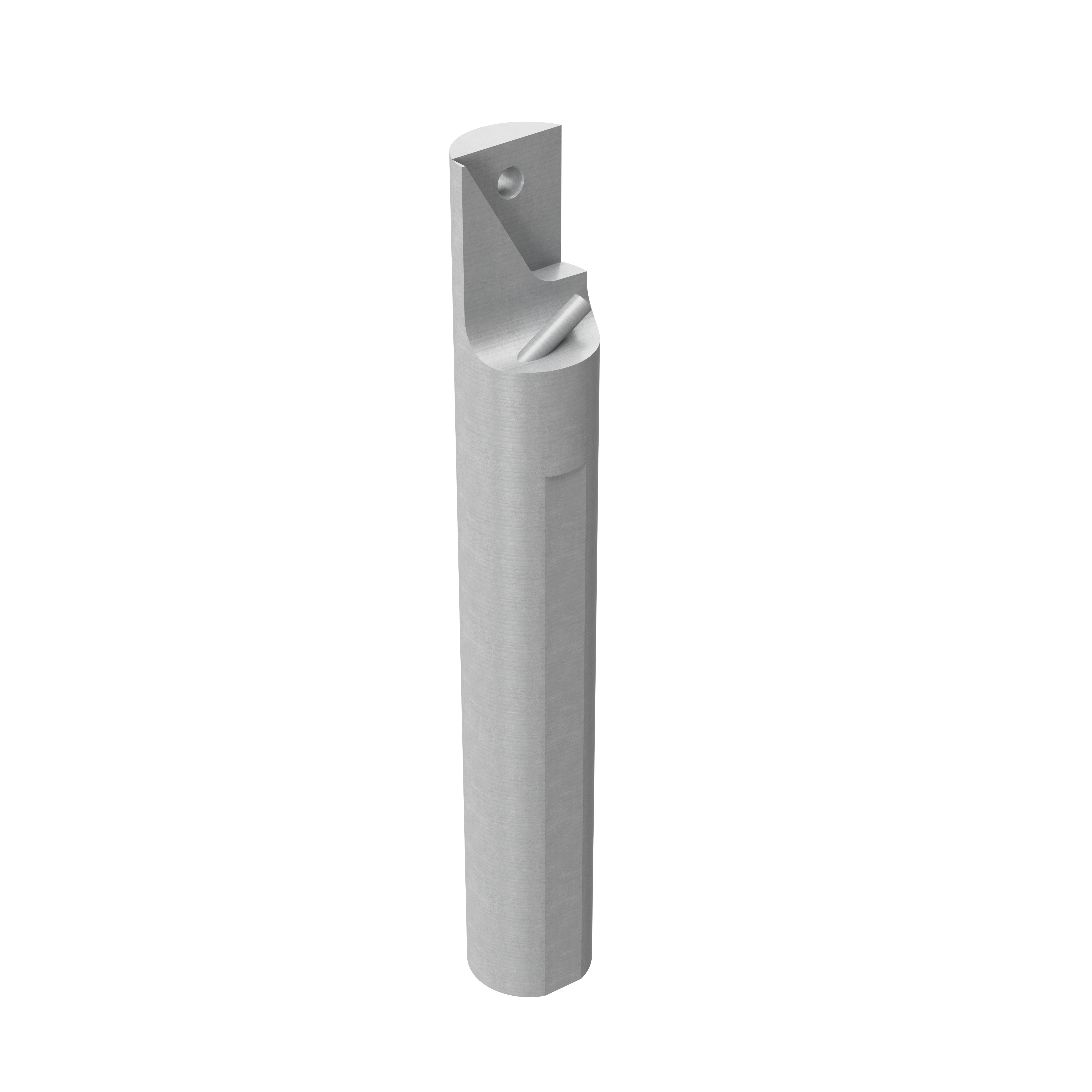

H13

17-4PH

17-4PH

Ti-64

17-4PH

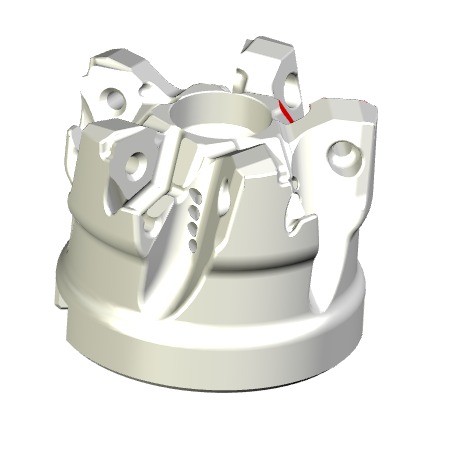

H13

Tungsten carbide (WC)

Titanium

H13

17-4PH

17-4PH

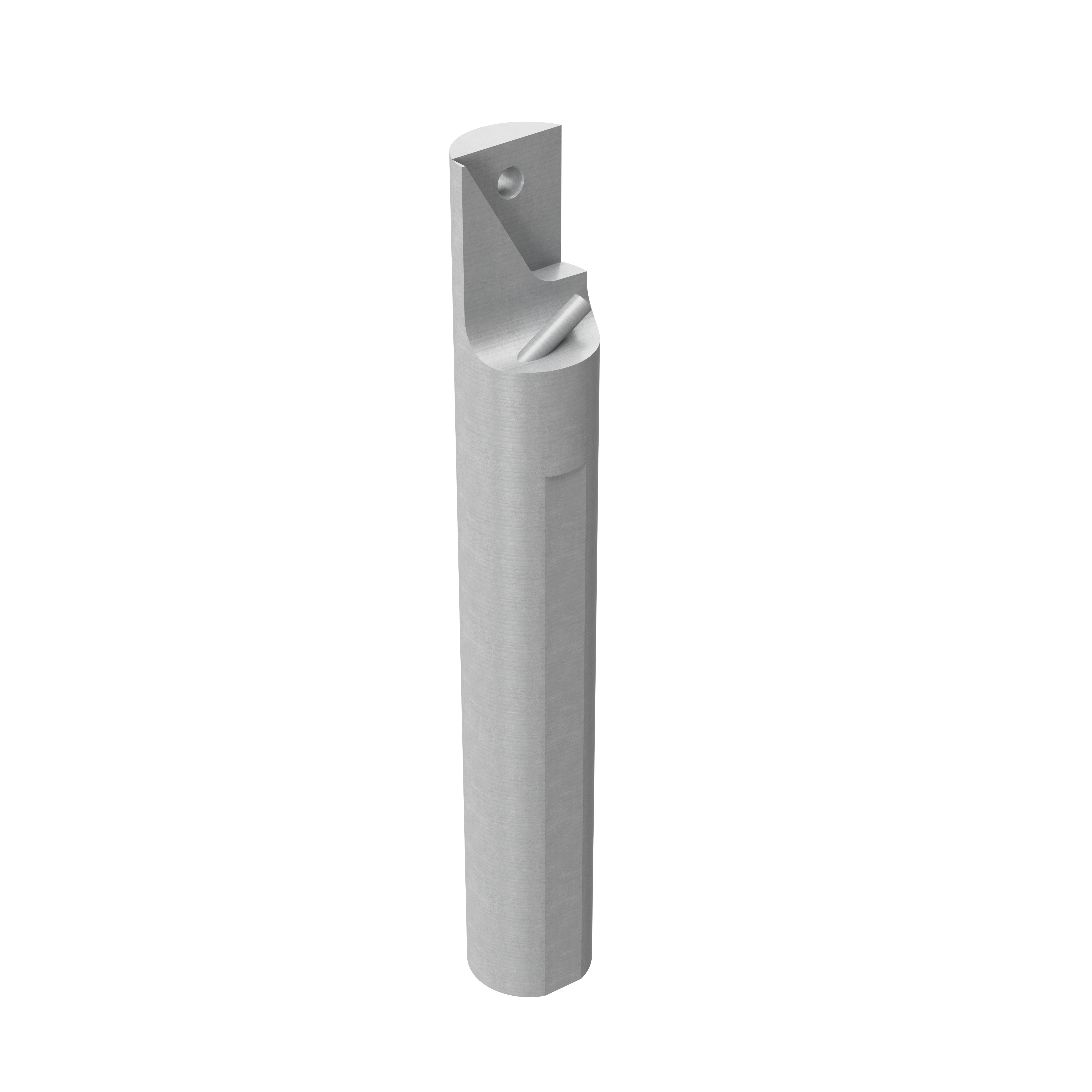

Ti-64

17-4PH

H13

Tungsten carbide (WC)

Titanium

H13

17-4PH

17-4PH