Formnext is always the place to take the pulse of the additive manufacturing world — a concentrated look at where technologies are maturing, where industries are investing, and where the next wave of disruption will come from. This year, the message was clear: metal AM is transitioning from experimentation to industrialization, and the companies that will lead are those who can deliver true, reliable, factory-ready manufacturing.

1. The Industry is Moving Beyond Machines — Toward Industrial Automation

One theme stood out: the next step is not just better printers, but robots and automation that connect the islands of production.

Across the show floor, we saw early attempts at robotic arms transporting parts between stations, automated depowdering, and integrated QC modules. The AM industry finally recognizes that printing is only one step in a much longer workflow.

The future factory is a connected, automated line, not a cluster of isolated machines.

For us, this reinforced a core belief: metal AM becomes truly viable when the steps before and after printing are as controlled, predictable, and automated as the printing itself.

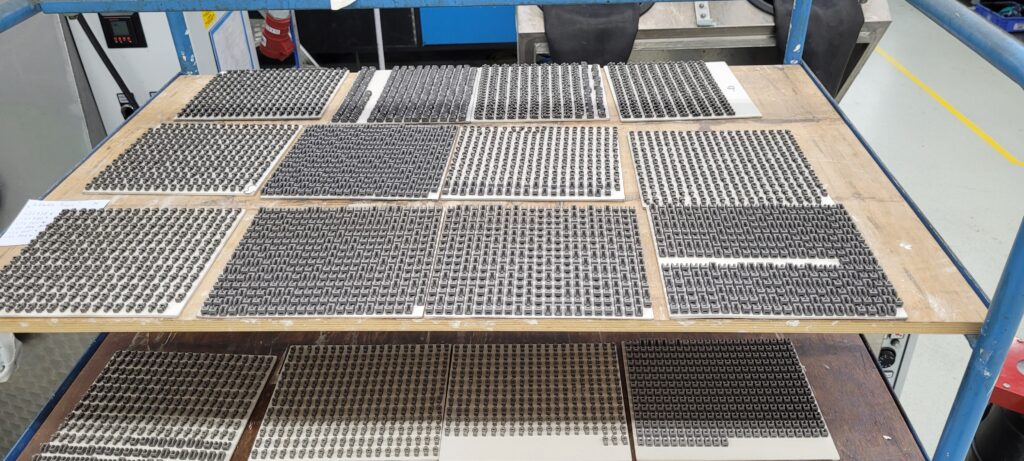

2. The Market no Longer Wants Prototypes — It Wants Industrial Production

Conversations with customers confirmed a major shift:

Prototyping is no longer the main value of AM. Manufacturers want real production.

Industries now measure technologies by:

- throughput

- repeatability

- automation level

- total cost of ownership

- supply-chain resilience

And the verdict is clear: systems that cannot meet industrial expectations will not survive the next stage of the market.

This is exactly where our MoldJet technology naturally fits — enabling high-volume, high-quality metal and ceramic production without the constraints of powder-bed systems.

3. A Strong Focus on Precious Metals, Materials, and Jewelry Applications

So much is happening around precious metals and specialty materials, especially for the jewelry and luxury goods sectors.

These industries are pioneering new alloys, surface qualities, and AM-ready materials. Many R&D efforts shown at Formnext — from refinements in metal powders to specialized post-processing — were dedicated almost entirely to metal AM for high-value applications.

It’s a segment where traditional manufacturing has clear limitations and AM’s freedom of design delivers immediate value.

4. The Biggest Barrier in Metal AM Remains the Furnace

Across the entire metal AM community, one challenge dominates all discussions:

Sintering is still the bottleneck.

Sinter-based processes — including bound metal AM, FFF, and certain binder jet workflows — all hinge on one critical question:

Can your part survive the furnace?

The sintering step is where most failures occur, quality is lost, or production becomes unpredictable. At Formnext, many companies openly acknowledged that the furnace is the real gatekeeper of industrial adoption.

What the industry lacks today is:

- standardized sintering protocols

- globally accessible, trusted sintering hubs

- predictable, repeatable sintering outcomes

- shared knowledge and infrastructure

The next leap in metal AM will be the creation of a global sintering network — a distributed ecosystem of certified sintering centers that ensure quality, speed, and cost-effectiveness regardless of geography.

This alone would dramatically lower the barriers to adoption.

5. Our Partnership with Stratasys Highlights an Urgent Market Need

The partnership with Stratasys was one of the strongest validations of this industry shift.

Stratasys — one of the world’s leading AM companies — has dominated polymer AM for decades. Their decision to partner with Tritone underscores a simple truth:

Customers now demand industrial metal solutions alongside advanced polymer solutions.

Polymer AM is mature. Metal AM is maturing quickly. But manufacturers want a unified, production-ready ecosystem, and together Tritone + Stratasys bring exactly that.

This collaboration is not just a partnership; it is a signal to the market that industrial-grade AM is the new standard.

6. What We Hope to See Next: Lower Barriers, Higher Confidence

If Formnext is a preview of the future, here’s what we believe the next stage must deliver:

✔️ Metal AM without fear of the furnace

The furnace should not be an unpredictable final exam for every part — it should be a controlled, reliable step in a seamless workflow.

✔️ A global, accessible sintering network

Lowering the adoption barrier through shared infrastructure will accelerate the entire metal AM ecosystem.

✔️ Clear understanding of the value of metal AM

Manufacturers should not adopt AM because it’s innovative — but because it unlocks geometries, efficiencies, and design possibilities that traditional processes cannot.

✔️ Industrial-scale production as the baseline

Metal AM should be judged by uptime, throughput, part consistency, and cost — not by one-off demonstrations.

Final Thoughts

Formnext 2025 made one thing clear: the future of AM belongs to technologies that can deliver real industrial production, not prototypes.

Metal AM is at a crossroads, and the winners will be those who automate workflows and offer reliable, scalable solutions.

At Tritone, we believe this future is closer than ever — and together with our partners and customers, we’re building it now.