the industrial solution for metal & ceramic manufacturing

Any Material at an Industrial Scale

High Throughput

High-speed, high-volume,

high-performance manufacturing — every part, every time

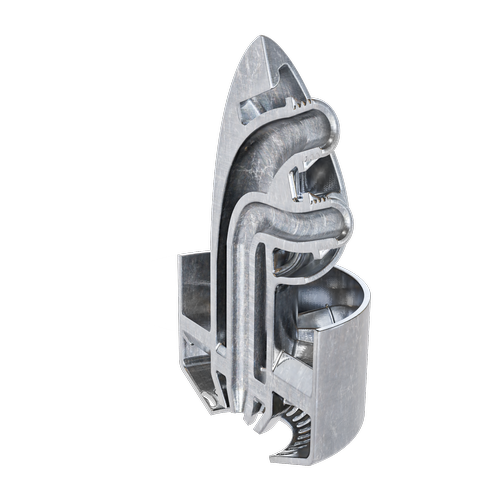

Industry Standard Material Properties

Ready for anyalloy, our parts match the strength, durability, and performance of industry-standard materials

High Repeatability

Unmatched consistency —precision manufacturing that delivers the same flawless result, every time.

Developed for Mass Production

Tritone revolutionizes metal Additive Manufacturing to meet the high standards of industrial production.

Our innovative technology empowers efficient production of precise parts in various metals and ceramics, serving industries such as Automotive, Aerospace, Medical, and Consumer Electronics.

Our benefits

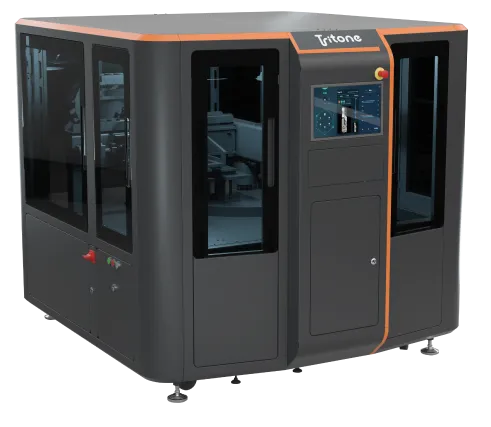

our manufacturing systems

dominant

- Number of trays: 6,

simultaneous and independent - Throughput: Up to 1,600 cc/h

- Total build volume: 70,000 cc

Dim

- Number of trays: 4,

simultaneous and independent - Throughput: 220 cc/h

- Total build volume: 10,000 cc